HOME

案例實績

Alcoholic Drink & Beverage

Filter cartridge suitable for mineral water production

2025-09-22

Filter cartridge suitable for mineral water production

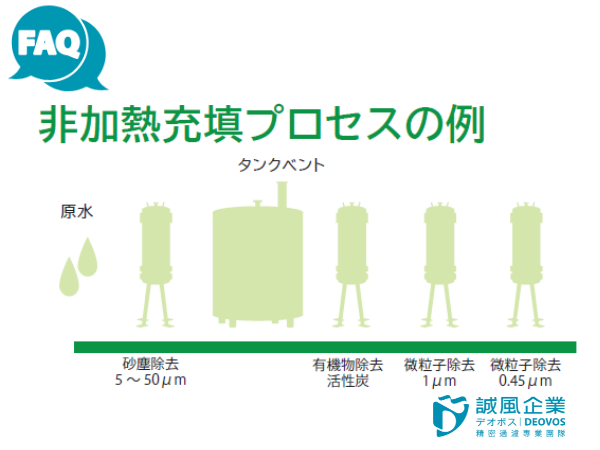

Below is a sample process for packaging mineral water.

Source: Application example provided by ROKI.

(This is for reference only; individual drinking water production processes may vary slightly.)

Raw Water >>> Primary Filtration (Grit Removal) >>> Storage Tank >>> *** >>> Activated Carbon (Organic Matter Absorption/Odor Removal)

>>> Pre-Filtration (Removal of Small Particles and Activated Carbon Particles)

***Due to slight variations in water quality across Taiwan, some customers add resin to the pre-activated carbon filter to adjust its hardness.

***Since packaged mineral water cannot be sterilized by heat, other methods must be used to remove microorganisms.

Some customers choose UV or ozone treatment.

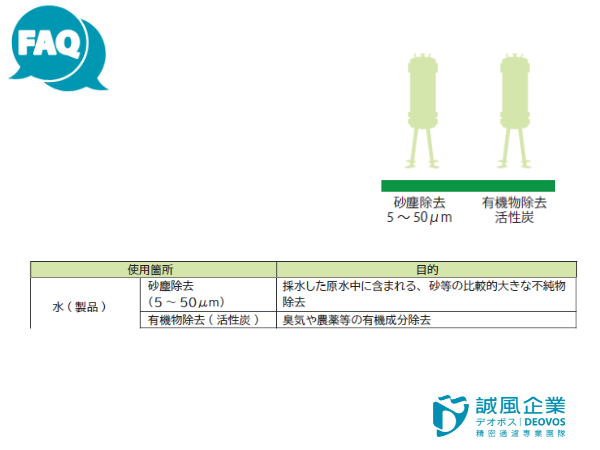

Filtration products used in each stage

Primary Filtration (Grit Removal) >>> A wide range of filter options are available, including primary filter bags, spiral wound filter cartridges, and deep filter cartridges to achieve the desired effect.

Activated Carbon >>> Mainly functions to adsorb organic matter and remove odors. Adsorption efficiency varies depending on the carbon source.

Resin (Cationic and Anionic Resins) >>> Mainly functions to adjust the hardness of water.

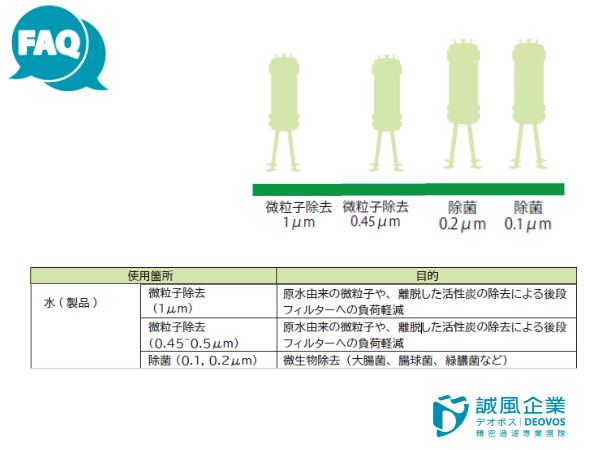

Pre-filtration (removing particles smaller than 1µm) >>> Pleated filter cartridges are recommended. Fiber or membrane filters can be selected based on product requirements.

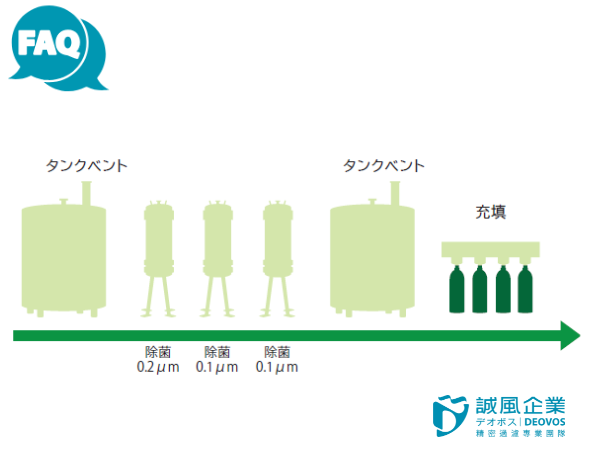

Final filtration (0.2µm filter cartridges with sterilization) >>> Pleated filter cartridges are recommended. PES or PS membrane filters are typically used.

Other Places Where Filters Are Used

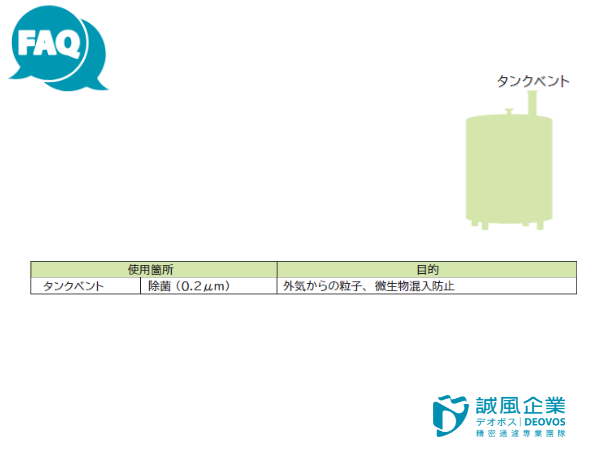

Temporary Storage Tanks >>> To prevent dirty air or suspended microorganisms from entering the tank, an air filter (or air valve) is typically installed here.

Filling Area >>> Use clean air to clean the filling bottles.

It is recommended that the filters in the above locations use hydrophobic PTFE membrane filters. If you would like to know why, please contact DEOVOS Sales for further discussion!

At DEOVOS Enterprise, we often say, "There's no best filter, only the most suitable filter."

The DEOVOS Enterprise team can provide the most suitable method based on your product needs.

Please mail your needs to the following mailbox.

There will be dedicated staff at your service.

service@deovos.com.tw